A basic distinction is made between torque tools for the hand tightening or machine-operated tools. Manual tightening tools are, for example, torque wrenches or torque screwdrivers. Mechanical screwing can be done hydraulically, pneumatically or electrically (also battery).

Torque tools for manual tightening

The maximum tightening torque is limited by the force that the user can apply and the length of the lever. Example: With a lever length of 1,900 mm, the theoretical limit is 2,000 Nm (Newton meters). Torque tools for manual tightening include torque wrenches or Torque screwdrivers. If certain torque values cannot be achieved by hand tightening, a torque multiplier can help. This multiplies the input torque (up to 22:1). If you want to test or calibrate torque tools, torque testers will help.

Examples: Maintenance, repairs and assemblies in many areas of application, mechanical and plant engineering, power plants, the automotive sector, and much more.

Torque wrenches

Technical design

A distinction is made between mechanical (classic) torque wrenches and electronic models. Mechanical models are used in most cases, not least because of their robustness and cost reasons. Here, too, there are different approaches depending on the brand: Stahlwille, for example, uses a torsion bar.

Torsion bar

No need to reset to zero. Low-wear release system with flexible rod. In contrast to conventional torque wrenches, it is not necessary to reset to "0" to relieve the spring. This results in a long-term display reliability of the desired torque value.

Head and drive

Basically, a distinction is made between torque wrenches for inserting the drive tool (insert tools such as ratchets) and those that use the ratchet head permanently installed. With those wrenches that use insert tools, there are again differences depending on the manufacturer. The drive takes place via a square, a rectangular or a round insert. The advantage of torque wrenches is their flexible use: There are inserts like ratchets, open ended spanners, ring, torx, hexagon and much more. The drive (e.g. the square of the wrench) is often determined by the application (e.g. size of the socket) itself. These range from small areas such as 1/4 inch to high up to 1 1/2 inches. A wide range of applications can thus be covered.

Releasing or displaying

Releasing means that you can use the torque wrench to tighten a screw, for example and the wrench is triggered at a certain torque value (usually Nm). I.e. the tightening process is stopped, the screw has reached the desired value. In mechanical models, this is usually a click or cracking noise (can be felt in the hand), electronic models also offer the option of an optical display (e.g. green LED - red LED). The torque values are defined in advance on a scale or a display. Indicating torque wrenches must never be used for tightening. I.e. these wrenches are to be used only to check the torque value!

Special functions

Torque function/ angle of rotation function: Here, for example, the screw is tightened with a certain, defined angle of rotation. This means that an angle is added to the torque value. Example: Tightening = 50 Nm + 90°. That means a suit with 50 Newton meters (joining torque/ threshold value) and 90° angle from the threshold value.

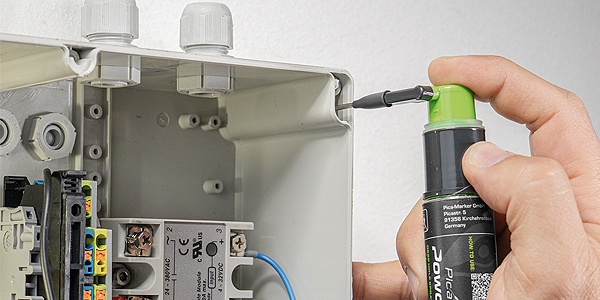

Torque wrench with marking function: As soon as the torque wrench has reached the desired tightening value, it is Brandd with a quick-drying ink. Tightening and marking takes place in one operation!

Normalization

Torque wrenches are subject to the standard EN ISO 6789: 2017-07. This recommends a recalibration interval after a period of use of 12 months or about 5,000 load changes. We are happy to offer you our calibration service for torque wrenches!

Did you know: The world's first self-releasing torque wrench was patented in 1938 and brought onto the Brandt (Saltus-Werk Max Forst, Solingen).

Models

Torque wrenches for special areas

-

VDE torque wrenches

Torque wrench for the ranges 4 to 50 Nm.

learn more -

Non-sparking torque wrenches

Torque wrench for the ranges 30 to 150 Nm.

learn more -

Stainless steel torque wrenches

Torque wrench for the ranges 2.5 to 200 Nm.

learn more

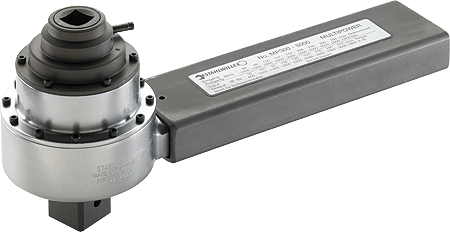

Torque multipliers

In the event that the desired torque cannot be achieved with manual tightening, so-called torque multipliers can help. With the help of a planetary gear (translation) the tightening and loosening force is increased. This means that tightening ratios (input torque to output torque) of up to 1:22 can be achieved.

Torque screwdrivers

Technical design

As with torque wrenches, a distinction is made between mechanical and electronic models. The working environment, the application and the cost factor determine the choice of torque screwdriver. Possible fields of application: production and repair areas, small appliance construction, pharmaceuticals, medical technology, laboratories.

For tightening or testing

For tightening, the torque screwdriver is mostly used to achieve very small, defined torque values. The mechanical models mostly have a rotary slip mechanism (when the torque value is reached, the handle slips through without further tightening), digital models use acoustic and LED signals as an additional stop mechanism. Torque screwdriver for testing is mostly found as a torque screwdriver or as a test dial gauge.

Special functions

Torque screwdriver with marking function

As soon as the torque screwdriver has reached the desired tightening value, a mark is made with a quick-drying ink. Tightening and marking takes place in one operation!

| Brand | Type | Range cNm | Tool holder | Graduation cNm | Accuracy +/-% | Picture |

|---|---|---|---|---|---|---|

| Tohnichi | mechanical | 0.3-400 | 1/4" Bits | 0.05-10 | 3 | |

| Stahlwille | mechanical | 15-600 | 1/4" Bits | 2.5-20 | 6 |

Torque testers

These are used for checking and calibrating of torque wrenches and torque screwdrivers. Torque wrench testers essentially consist of a basic unit and a sensor. The linear movement is converted into a rotary movement. This signal is transmitted to the PC with the appropriate software and can thus be documented and used, for example, for the creation of calibration certificates.

Torque tools for machine tightening

If the manual force is no longer sufficient to tighten or loosen a screw connection or if the application is too difficult, a machine-operated device is usually used. These torque tools achieve torques of up to (around) 48,000 Newton meters (Nm). A distinction is made between the type of operation: hydraulic, electrical/ battery or pneumatic.

Examples: maintenance, assembly, machine and plant construction, steel constructions in crane construction, power plants, oil and gas production as well as all serious screwdriving cases.

Hydraulical drive

Square drive for sockets

The square offers the advantage, that impact sockets can be attached directly to them. The drives range from 3/4 to 2 1/2 inches, the nominal torque is 1,952 to 35,455 Nm, the accuracy is +/- 3%, the weight ranges from 3 to 32 kg for the large torque ranges. Thanks to the square drive (directly attached), they are completely variable in terms of the wrench size required by their application. It is driven by a hydraulic pump.

This drive is particularly suitable for the direct use of Impact sockets. The nut can be plugged directly onto the drive unit. No adapters or anything else are required!

Square drive

| Model | Range Nm (min) | Square inch | Weight kg |

|---|---|---|---|

| S1500X | 1,952 (195) | 3/4 | 3.2 |

| S3000X | 4,373 (438) | 1 | 5.6 |

| S6000X | 8,338 (834) | 1 1/2 | 9.2 |

| S11000X | 15,151 (1,516) | 1 1/2 | 15.8 |

| S25000X | 35,455 (3,545) | 2 1/2 | 32.2 |

Drive unit with cassette (hexagonal)

A drive unit and a cassette are used for bolting. The drive unit defines the newton meter range. This means that the application requires a certain loosening or tightening torque. The drive units cover a range from 2,766 to 47,454 Nm. Then you choose a cassette (insert). This enables bolting in certain wrench sizes. If the application requires a wrench size that differs from the range of the cassette, a so-called reducing insert can help. The big advantage of this bolting method is the possibility of placing the torque wrench directly on the nut. The display deviation is +/- 3%. Here too, it is driven by a hydraulic pump.

A hydraulic torque wrench with a hexagonal drive has the advantage that it is easier to work under occupied space and that the flat device can also screw in narrow gaps.

Hexagonal drive

| Drive unit | Range Nm (min) | Cassette size mm | Drive unit kg |

|---|---|---|---|

| W2000PX | 2,766 (276) | 30-60 | 1.4 |

| W4000PX | 5,661(566) | 36-80 | 2 |

| W8000PX | 11,484 (1,148) | 50-105 | 3 |

| W15000PX | 20,785 (2,078) | 65-115 | 5 |

| W22000PX | 30,506 (3,050) | 75-135 | 7.7 |

| W35000PX | 47,454 (4,745) | 80-155 | 11.72 |

Combined drive: One device for square and hexagonal

A variably usable hydraulic torque wrench, the drive unit can be used with both hexagonal and square cassettes. Depending on the application, a drive cassette in square or hexagonal design is selected. The device has a display deviation of +/- 3%.

| Model | Range Nm | Cassette size mm | Drive unit kg |

|---|---|---|---|

| RSL1500 | 1,909 | 26-60 | 1.6 |

| RSL3000 | 4,176 | 33-75 | 2.6 |

| RSL5000 | 7,190 | 46-80 | 4.1 |

| RSL8000 | 10,659 | 60-80 | 4.9 |

| RSL11000 | 15,123 | 62-110 | 5.3 |

| RSL19000 | 25,547 | 75-115 | 9.1 |

| RSL28000 | 37,965 | 80-155 | 10 |

Power units for

hydraulic torque wrenches

The pumps are operated either with electricity, with a battery or pneumatically (compressed air). Electric pumps are the most common, battery pumps are ideal in locations where there is no electricity.

Electrical and battery operated

WIFI torque machine

Data is transferred wirelessly with WI-FI or via USB port. This provides a convenient documentation function. Suitable for screw connections in the Nm range from 50 to 900. With the new Juwel TQX torque wrench, digital, precise torque screwing with a documentation function becomes an easy task.

Functions

- User-friendly display for programming and display of results

- up to 1,200 screwdriving processes can be saved

- Data can be transmitted wirelessly (WI-FI and USB connection)

- up to 8 screw configurations can be saved

- Control by brushless DC motor

- Efficient magnetic drive

- High-precision torque measurement

- Angle control and torque monitoring

| Torque Nm | Drive inch | Speed rpm | Weight kg | Item number |

|---|---|---|---|---|

| 50-600 | 3/4 | 10 | 4,25 | 2700-820 |

| 50-900 | 3/4 | 8 | 6,30 | 2700-830 |

| 50-900 | 1 | 8 | 6,30 | 2700-840 |

Battery torque machines

The drive is powered by a battery (18 volt, 5 Ah, battery charge in less than 30 minutes), the power socket wrench inserts can be attached to a square (3/4 to 1 1/2 inch), the nominal torque ranges from 150 to 5,000 Nm, the Designs are straight or angled. For series screw connections or in maintenance: When exact torques are a prerequisite and the work has to be mobile! The cordless screwdriver is ideal for mobile use, for example when maintaining track systems.

| Type | Range Nm | Square inch | Weight kg (straight/ angled) |

|---|---|---|---|

| straight | 50-650 | 3/4 | 4.75 |

| straight/ angled | 100-950 | 3/4 | 6.8/ 8.8 |

| straight/ angled | 100-1,300 | 1 | 6.9/ 9.3 |

| straight/ angled | 100-2,200 | 1 | 8.2/ 10.1 |

| straight/ angled | 100-3,000 | 1 | 8.3/ 10.1 |

| straight/ angled | 150-4,000 | 1 1/2 | 8.5/ 12 |

| straight/ angled | 300-5,000 | 1 1/2 | 11.7/ 14.2 |

Weight information including reaction arm.

View PDF fileBattery torque machine

Mit Bluetooth data transfer from Tohnichi. The screwing solution for the range from 2 - 10 Nm.

The new cordless torque wrench (18 V) makes your work easier. Successful screw connections are indicated to you by a signal (blue = good; red = bad). The wrench recognizes a second round of tightening to prevent this error (Pokayoke). A torque increase at insufficient turning angles caused by "biting" is detected. Anomalies during tightening are also detected (e.g. thread contamination and internal thread errors).

With torque sensor and angle of rotation sensor, display accuracy +/- 5%, upper and lower tightening torque limits and angle can be set via the button input function on the shaft or via Bluetooth using the software will. The tightening data can also be transmitted via Bluetooth.

Torque machines

(electrical)

The drive is electrical (230 volts), the impact sockets can be attached to a square (3/4 to 1 1/2 inch), the nominal torque ranges from 150 to 10,000 Nm, there are straight and angled models.

Best if there is enough space for the screw connection.

straight form

Ideally suited for tight spaces.

angled form

| Type | Range Nm | Square inch | Weight kg (straight/ angled) |

|---|---|---|---|

| straight/ angled | 150-850 | 3/4 | 9.6/ 11.1 |

| straight/ angled | 280-1,200 | 1 | 9.8/ 11.5 |

| straight/ angled | 360-2,500 | 1 | 11.1/ 13.1 |

| straight/ angled | 360-3,500 | 1 1/2 | 13.9/ 15.8 |

| straight/ angled | 700-5,000 | 1 1/2 | 16.1/ 17.9 |

| straight/ angled | 816-6,000 | 1 1/2 | 21.6/ 23.7 |

| straight/ angled | 1,024-10,000 | 1 1/2 | 24.6/ 26.5 |

Weight information including reaction arm.

View PDF fileBolting documentation

If you do not only want to screw, but also document the individual bolting process, we recommend the T-DOC. You can see the tightening torques on a digital display, 999 storage spaces are available, the battery life is more than 8 hours. The screw connections can be transferred to the PC using a USB cable. The accuracy is +/- 1%.

Pneumatic bolting

Pneumatic bolting is less common but may be desirable in certain cases. In this segment we offer the option of a selection of small devices (range Nm: 5-180) to cover large Nm ranges (up to 8,135).

| Brand | Range Nm | Tool holder square inch | Accuracy +/-% | Picture |

|---|---|---|---|---|

| Tohnichi | 5-180 | 3/8. 1/2 | 3 | |

| Enerpac | 407-8,135 | 1. 1 1/2 |